Stepper Drivers in Action: CNC, Robotics, and Automation with USB & Modbus Control

Stepper motors are the backbone of precision motion control in countless applications, from 3D printers and CNC machines to industrial automation and robotics. At the heart of every stepper motor system lies a critical component—the controller or driver—that dictates the motor’s performance, accuracy, and responsiveness.

In this comprehensive guide, we will explore four essential topics in the realm of stepper motor control: the PoStep60-256, a powerful and versatile stepper motor driver; the USB stepper motor controller, a modern solution for seamless computer-based motion control; the fundamentals behind how a stepper motor driver explained in detail to demystify its operation; and finally, the Modbus stepper driver, which brings industrial communication protocols into the mix for advanced automation.

Each of these subjects plays a crucial role in optimizing stepper motor performance, whether for hobbyist projects or industrial-grade systems. By the end of this article, you will have a deeper understanding of how these controllers and drivers function, their key features, and how they can be applied in real-world scenarios. Let’s dive into the intricacies of stepper motor control and uncover what makes these devices indispensable in precision motion applications.

What is the PoStep60-256 and How Does It Work?

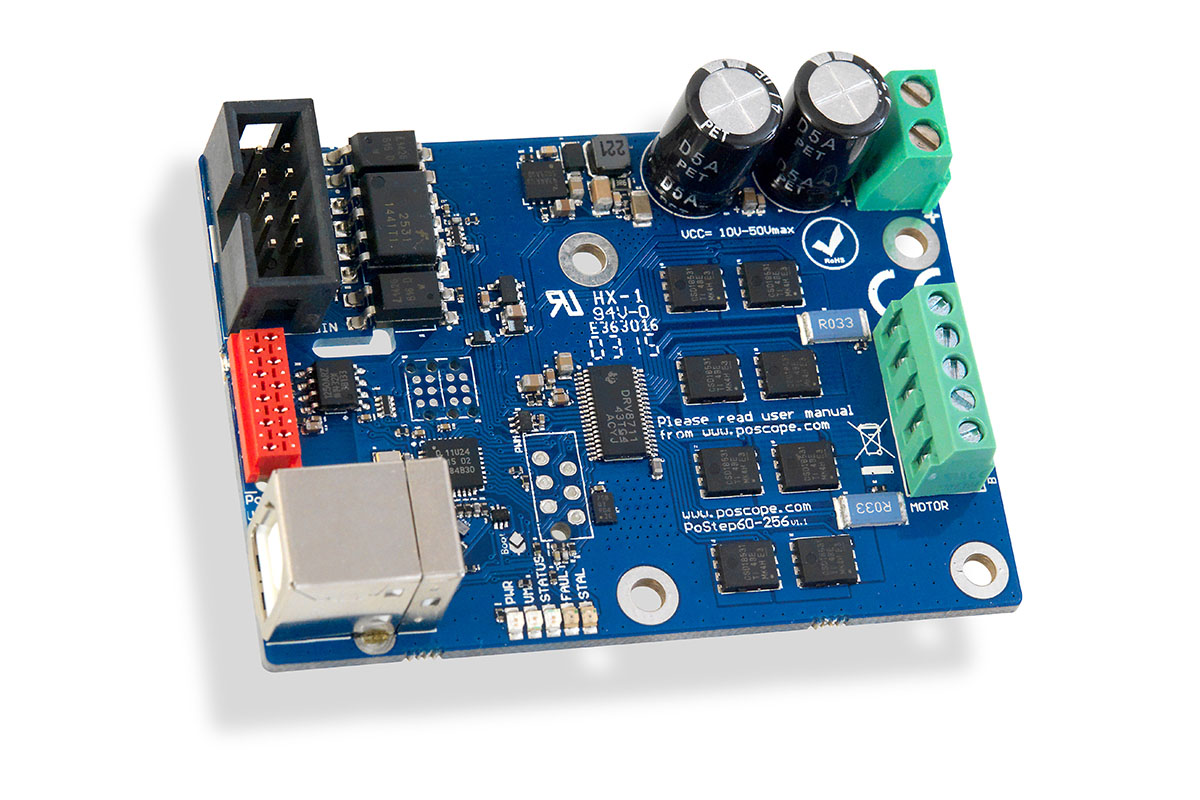

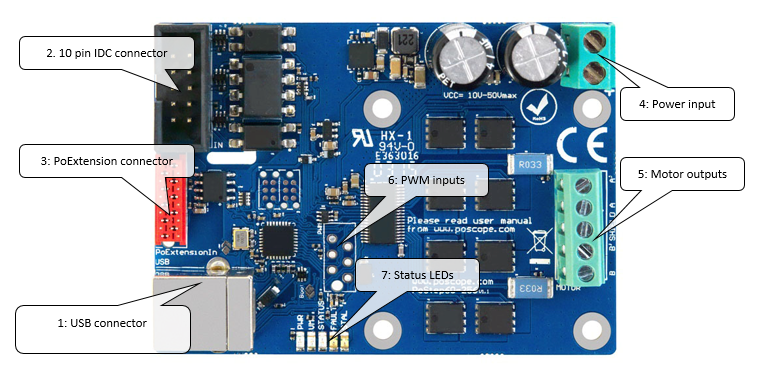

The PoStep60-256 is a high-performance stepper motor driver designed for precision motion control applications. Combining advanced microstepping technology, robust power handling, and intelligent control features, this driver is a popular choice among engineers, CNC enthusiasts, and automation professionals. But what exactly makes the PoStep60-256 stand out, and how does it function within a motion control system?

At its core, the PoStep60-256 is a digital stepper motor driver capable of delivering up to 60V and 6A per phase, making it suitable for driving high-torque stepper motors efficiently. One of its defining features is its 256x microstepping capability, which allows for exceptionally smooth and precise motor movements. Unlike traditional full- or half-step drivers, microstepping divides each motor step into smaller increments, reducing vibration, noise, and mechanical resonance while improving positional accuracy.

Another key advantage of the PoStep60-256 is its adaptive current control, which dynamically adjusts the motor current based on load conditions. This not only optimizes performance but also prevents overheating and energy waste. Additionally, the driver supports multiple control interfaces, including step/direction signals and UART communication, providing flexibility for integration into various systems.

A critical aspect of the PoStep60-256 is its protection mechanisms, such as overvoltage, undervoltage, overcurrent, and short-circuit safeguards. These features ensure reliable operation even in demanding environments. Furthermore, the driver includes advanced diagnostics, allowing users to monitor motor performance and troubleshoot issues efficiently.

In practical applications, the PoStep60-256 is often used in CNC machines, 3D printers, robotic arms, and automated manufacturing equipment. Its ability to handle high power while maintaining precision makes it ideal for scenarios where both speed and accuracy are crucial. Whether controlling a single motor or part of a multi-axis system, the PoStep60-256 delivers consistent and dependable performance.

Ultimately, the PoStep60-256 represents a blend of power, precision, and intelligence in stepper motor control. By leveraging microstepping, adaptive current management, and robust protection features, it ensures smooth and efficient motor operation, making it a top choice for advanced motion control applications.

What is a USB Stepper Motor Controller and Why Use One?

In the world of motion control, USB stepper motor controllers have become a game-changer, offering a seamless bridge between computers and stepper motor systems. Unlike traditional controllers that rely on standalone hardware or complex wiring, a USB stepper motor controller simplifies connectivity by plugging directly into a PC or embedded system via a standard USB port. But how exactly does this type of controller work, and what advantages does it bring to stepper motor applications?

A USB stepper motor controller acts as an intermediary between software-based motion commands and the physical stepper motor driver. It receives step and direction signals from a computer program—such as CNC software, custom automation scripts, or lab control systems—and translates them into precise electrical pulses that drive the motor. This setup eliminates the need for additional pulse generators or microcontroller programming, making it an accessible solution for both hobbyists and professionals.

One of the biggest benefits of using a USB stepper motor controller is its plug-and-play simplicity. Since USB is a universally supported interface, these controllers can be quickly integrated into existing setups without specialized hardware. Many models also include user-friendly configuration software, allowing for real-time tuning of motor parameters like speed, acceleration, and microstepping resolution.

Another advantage is real-time control and feedback. Advanced USB stepper motor controllers support bidirectional communication, meaning they can send data back to the host computer—such as position feedback, error alerts, or temperature readings. This feature is particularly valuable in automation and research applications where monitoring and adjustments are necessary.

Additionally, USB stepper motor controllers are highly scalable. A single USB hub can support multiple controllers, enabling synchronized multi-axis motion control without complex wiring. This makes them ideal for applications like 3D printing, laser engraving, pick-and-place machines, and automated test equipment.

Despite their convenience, USB stepper motor controllers do have limitations. USB cables have length restrictions, and the system’s performance can be affected by the host computer’s processing load. However, for most small to medium-scale applications, the ease of use, flexibility, and cost-effectiveness of a USB stepper motor controller make it an excellent choice.

By combining computer-based precision with straightforward connectivity, USB stepper motor controllers provide an efficient and modern approach to motion control, reducing complexity while expanding possibilities in automation and robotics.

Stepper Motor Driver Explained: How Does It Control Precision Motion?

A stepper motor driver is the critical link between a control system and a stepper motor, responsible for translating electronic signals into precise mechanical movement. But how exactly does a stepper motor driver function, and what makes it indispensable in applications requiring accuracy and repeatability? Understanding its operation demystifies why these devices are fundamental in CNC machines, robotics, 3D printing, and industrial automation.

At its most basic level, a stepper motor driver receives low-power step and direction pulses from a controller—such as a microcontroller, PLC, or motion card—and amplifies them into the high-current signals needed to energize the motor’s coils in sequence. This phased activation creates magnetic fields that rotate the motor’s rotor in discrete steps, hence the name “stepper.” However, modern drivers go far beyond simple on/off switching, incorporating features that enhance performance, efficiency, and smoothness.

One of the key innovations in stepper motor driver technology is microstepping. Instead of driving the motor in full steps (typically 1.8° or 0.9° per step), microstepping divides each step into smaller increments—often 16, 32, 64, or even 256 subdivisions. This reduces vibration, minimizes audible noise, and enables smoother motion, which is crucial for applications like microscopy stages or high-resolution CNC machining.

Current regulation is another critical function of a stepper motor driver explained. Rather than supplying a fixed current, advanced drivers use pulse-width modulation (PWM) to adjust the coil current dynamically. This prevents overheating and ensures consistent torque, especially at lower speeds. Some drivers even employ adaptive current control, reducing power when the motor is idle to save energy and minimize heat buildup.

Protection features are also integral to a reliable stepper motor driver. Overcurrent, overheating, and short-circuit safeguards prevent damage to both the driver and motor, while stall detection algorithms can alert the system if the motor encounters an obstruction. Such diagnostics are invaluable in automated systems where unexpected failures can disrupt production.

Ultimately, the stepper motor driver is what transforms a simple pulse train into controlled, precise motion. Whether in a DIY project or a high-end industrial machine, its ability to manage power delivery, implement microstepping, and ensure safe operation makes it the unsung hero of motion control systems. By mastering these functions, engineers and hobbyists alike can optimize performance for any stepper motor application.

What is a Modbus Stepper Driver and How Does It Enable Industrial Automation?

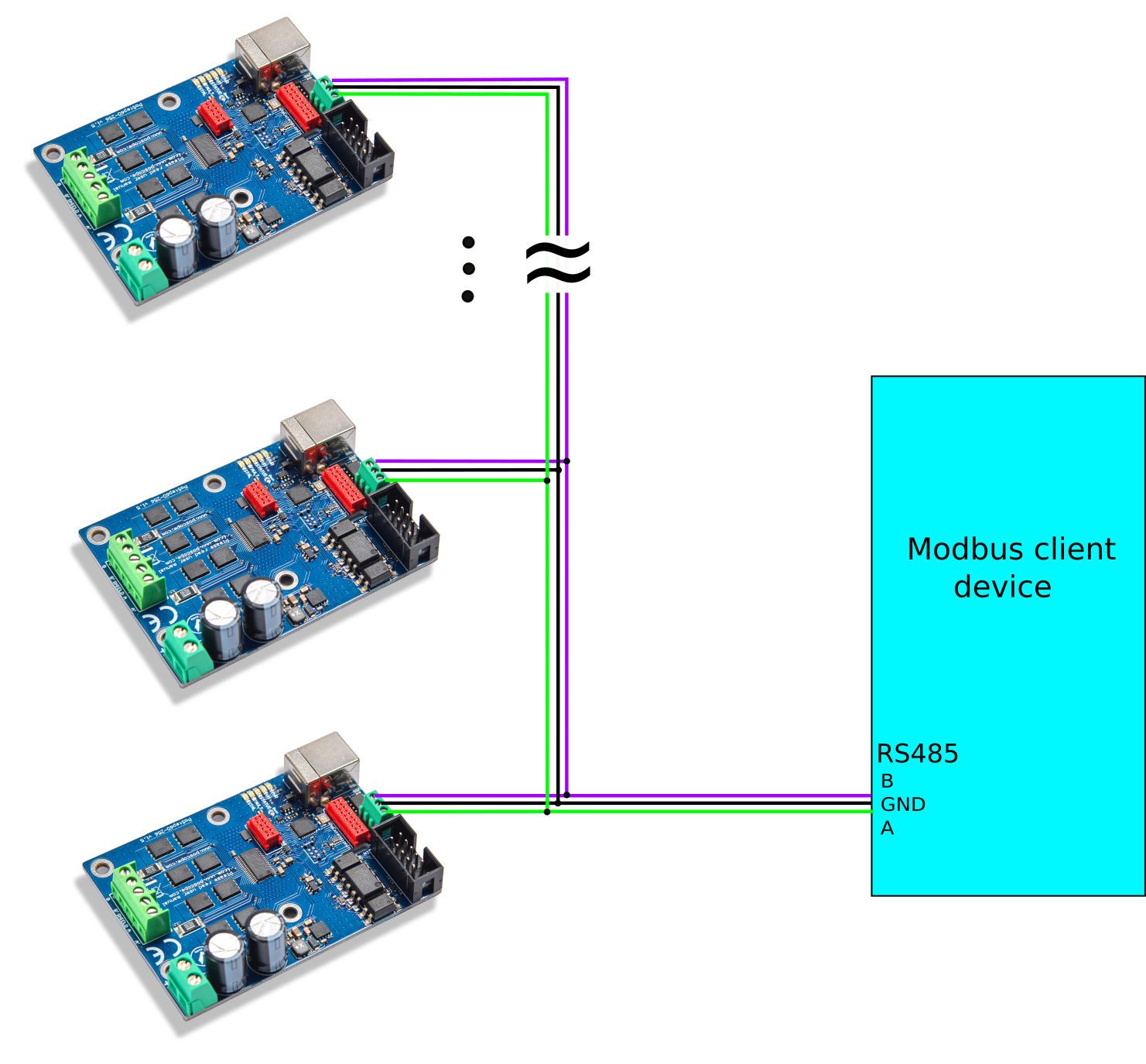

In industrial environments where multiple devices must communicate seamlessly, the Modbus stepper driver has emerged as a powerful solution for integrating stepper motors into networked control systems. Unlike conventional drivers that rely on direct step/direction signals, a Modbus stepper driver uses the Modbus communication protocol—a widely adopted standard in industrial automation—to receive commands and transmit data over serial (RS-485) or Ethernet networks. But how does this enhance motor control, and why is it indispensable in modern factories and smart machines?

The defining feature of a Modbus stepper driver is its ability to operate as a networked node, allowing centralized control from a PLC, SCADA system, or industrial PC. Instead of wiring individual pulse generators to each motor, engineers can daisy-chain multiple drivers on a single Modbus network, drastically reducing cabling complexity. This scalability makes the Modbus stepper driver ideal for multi-axis systems like conveyor belts, packaging machines, or automated assembly lines where synchronized motion is critical.

Precision control remains a hallmark of the Modbus stepper driver. Through Modbus commands, operators can remotely adjust microstepping resolution, current limits, acceleration profiles, and target positions in real time. Some advanced models even support closed-loop feedback by reporting actual motor position, load conditions, or fault status back to the host controller—enabling predictive maintenance and error recovery without manual intervention.

Another advantage is noise immunity and long-distance reliability. RS-485-based Modbus networks can span up to 1,200 meters (at lower baud rates), making them suitable for sprawling industrial facilities. The protocol’s error-checking mechanisms ensure data integrity, even in electrically noisy environments where traditional pulse wiring might suffer interference. Ethernet Modbus (Modbus TCP) variants offer even faster communication for high-speed applications.

While Modbus stepper drivers excel in industrial settings, they do require some familiarity with Modbus addressing and message framing. However, their compatibility with standard automation software (e.g., Ignition, LabVIEW, or CODESYS) simplifies integration. From textile machinery to semiconductor handling systems, the Modbus stepper driver bridges the gap between precision motion control and Industry 4.0 connectivity, proving that stepper motors still have a vital role in the age of smart manufacturing.

By combining robust communication standards with precise motor control, the Modbus stepper driver transforms standalone steppers into intelligent, networked components—future-proofing automation systems while maintaining the simplicity and cost-effectiveness that make stepper motors so widely adopted.

Why Stepper Systems Fail—And How the Right Driver, PoStep25-256, and Rigorous Testing Prevent It

Choosing the Right Stepper Motor Control for Your Application

From the microstepping precision of the PoStep60-256 to the plug-and-play convenience of USB stepper motor controllers, and from the foundational principles of a stepper motor driver explained to the industrial connectivity of Modbus stepper drivers, this guide has explored the critical technologies behind modern motion control. Each solution caters to distinct needs—whether it’s hobbyist projects demanding simplicity, labs requiring real-time feedback, or factories prioritizing networked automation.

As industries increasingly embrace IoT and smart manufacturing, the role of advanced stepper drivers will only grow. Understanding these tools empowers engineers to choose the right technology for precision, scalability, and reliability. Whether you’re building a 3D printer or automating a production line, the right driver ensures your stepper motors don’t just move—they perform.

By staying informed about innovations like closed-loop control, adaptive current management, and industrial protocols, you can future-proof your designs and unlock new possibilities in motion engineering. The journey from electronic pulses to mechanical motion is intricate, but with the right knowledge—and the right drivers—it’s a journey that leads to unparalleled control.